-40%

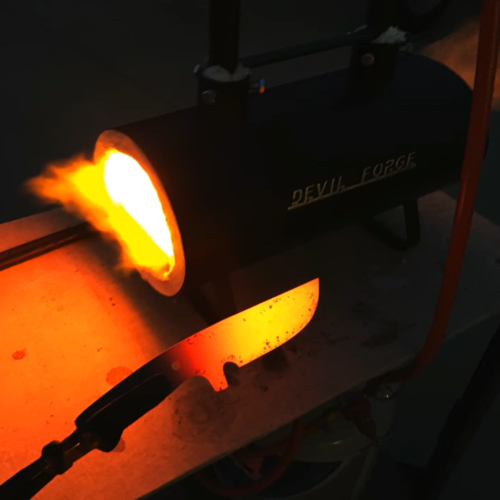

DFSW2 GAS PROPANE FORGE Furnace Burner Knife Making Blacksmith Farrier

$ 105.07

- Description

- Size Guide

Description

Untitled DocumentVisit Our Ebay Store: THE BIGGEST ASSORTMENT of Gas Forges, Gas Burners, Metal Melting Furnaces

DEVIL FORGE PRODUCT SETUP AND DEMONSTRATION VIDEOS

DFSW2 full set -

demo

INCLUDED REFRACTORY RIGIDIZER MUST BE APPLIED BEFORE USE.

Is included: rigidizer powder, brush and user manual. (See rigidizer application video above)

(Applying will provide extra strong protection and will increase durability for ceramic insulation)

One of these gas pressure regulators included depending on the country:

·

Gas regulator with

POL CGA-510

connection included for:

UNITED STATES, CANADA, SWEDEN, NORWAY, AUSTRALIA, NEW ZEALAND, ISRAEL, MEXICO, INDONESIA, THAILAND

·

Gas regulator with

G 5/8"UK POL LH

connection included for:

UNITED KINGDOM, SOUTH AFRICA

·

Our standard gas pressure regulator with connection - Shell DIN external thread to -

W21.8 x 1/14"LH

internal thread (Left thread) included for

all other countries

not mentioned above.

(Fits to GERMANY, AUSTRIA, FRANCE, NETHERLANDS, SPAIN, BELGIUM, SLOVENIA, FINLAND, POLAND, LATVIA, RUSSIA and other countries)

If you want a gas regulator other than mentioned for your country – let us know and we will adjust your order.

f

If you think that our gas regulator does not fit your gas tank, you can ADJUST THE SET

:

Without connection kit -

$

20 less.

When You make the payment please leave a note or a message

“Without connection kit”

and

we will refund that amount.

f

SHIPPING INFORMATION

Delivery time in European Union: 2-7 business days; USA, Canada: 5-8 business days; other countries: 5-12 business days. The packages are shipped via FEDEX, UPS, DPD, TNT. Very rarely the package can be shipped via regular post to extended areas, therefore shipping might be slower.

DFSW2, Propane Gas Forge for Knifemakers, Farriers and Blacksmiths, Efficient and Economical

Burners with gas ball valve! (Use 1 or 2 burners)

DFSW2 – 2 burner forge

Our DFSW2 forge is portable and powerful, high quality. Designed for blacksmiths, farriers and knife makers. We combined this forge with powerful DFP burners. We guarantee that You will reach welding temperature -

this forge can reach 2500

°

Fahrenheit (approx. 1370

°

Celsius).

DFP burner (80,000 BTU).

Powerful and efficient. Our nozzle design is lasting longer and increases the burner's efficiency. Its operating pressure range 1 - 25 PSI. There is a choke on the top of our burner – it regulates the amount of air that is mixed with the propane during combustion.

Note:

If You are looking for a good burner, You must know one thing – good burner must have air choke. If the burner doesn't have it (don't look at that side!), You can't reach maximum temperature because you need a different quantity of air on different pressure!

WATCH VIDEO “LESSON HOW TO REGULATE AIR CHOKE TO REACH IDEAL FLAME”

Specification DFSW2:

Burner

: DFP 2pcs. ;

Forge Body Constructed of

: steel 21 gauge (0.8mm), the shell is lightweight;

Interior Dimensions

: 6"Width x 4.8"Height x 16"Length (150mm x 120mm x 400mm); (Height with brick: 3,2"- 80mm);

Weight

: 16lb (7kg).

Interior of the forge is fully covered with a 1-inch ceramic blanket. The floor is made of firebricks, providing superior strength and durability.

Connection kit included with every forge:

Gas pressure regulator, gauge with manometer;

6.5 ft (2meters) gas hose;

2 clamps.

All you need to supply is the propane tank.

Our manometer with Mpa measurement. 0.1Mpa - 1Bar - 14.5PSI

The manometer advantages: You can adjust exact gas pressure You need and control gas consumption. You can see when the pressure is falling down.

Table explanation:

ATM: Gas pressure from gas pressure regulator (in Atmospheres). 1ATM - 1.01Bar - 14.5PSI

PSI: Gas pressure from gas pressure regulator (in Pounds per square inch). 1PSI - 0.06ATM - 0.068Bar

BTU/Hr: British thermal unit per hour. 1 BTU/hr = 0.00029307107 kW

LBS/Hr: Pounds per hour. 1 lbs = 0.45359237 kilograms

Kg/Hr: Kilogram per hour. 1 kilogram = 2.20462262 lbs

KW/Hr: Kilowatt per hour. 1 kW/Hr = 3412.142 BTU/Hr

DFP

PSI

ATM

BTU/H

lbs/h

KW/h

Kg/h

1

0,07

16.299

0,75

4,78

0,34

2

0,14

23.051

1,07

6,76

0,48

3

0,20

28.231

1,31

8,27

0,59

4

0,27

32.599

1,51

9,55

0,68

5

0,34

36.446

1,69

10,68

0,77

6

0,41

39.925

1,85

11,70

0,84

7

0,48

43.124

2,00

12,64

0,91

8

0,54

46.102

2,14

13,51

0,97

9

0,61

48.898

2,26

14,33

1,03

10

0,68

51.543

2,39

15,11

1,08

15

1,02

63.127

2,92

18,50

1,33

20

1,36

72.893

3,38

21,36

1,53

25

1,70

81.497

3,77

23,88

1,71

30

2,04

89.275

4,13

26,16

1,88

35

2,38

96.428

4,47

28,26

2,03

40

2,72

103.086

4,77

30,21

2,17

Graphic explanation:

BTU/Hr: burner power.

PSI: gas pressure from gas pressure regulator.

Illustrations may vary from actual product design, but the specifications are the same.

User manual in English is included.

Untitled Document